- other_housesHome

- Professionals

- Technical Planning Documents

- Wood Technical Planning Documents

Wood Technical Planning Documents

Pella® wood products are appropriate for a variety of wall conditions – whether for new construction, everyday renovation projects or high-profile historical restorations. And we have a full range of installation accessories to accommodate the installation of Pella windows and doors in virtually any structure.

New Construction

New Construction Methods of Attachment

There are four primary methods of attaching Pella® aluminum-clad wood windows in new construction: fins, clips, receptors and anchorage through the frame.

For an in-depth review of Pella's full range of installation systems and construction details for new construction, refer to the link below or contact your local Pella representative.

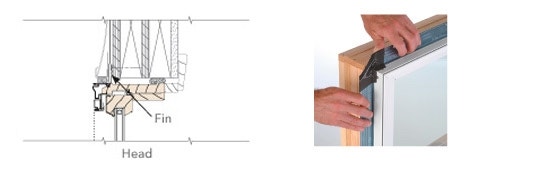

Fin Installation

Fin installation is applicable when construction methods permit window and door units to be installed from the exterior prior to the application of exterior cladding, such as lap siding, brick veneer or stucco.

Factory-Applied Aluminum Trim

Wood Brickmould

Clip Installation

Clip installation is applicable when construction materials or sequence dictates the window units be installed from the interior or after the wall system is completely constructed.

Receptor

Receptors are used for multistory buildings requiring installation from the interior or when a more robust installation method is desired.

Anchor Through Frame

New Construction Punched Openings

A facade created by the orderly placement of single or multiple windows in punched openings in a wall can be a strong design statement. With Pella's wide range of sizes and product types, your punched-opening design options are virtually unlimited.

Design Recommendations

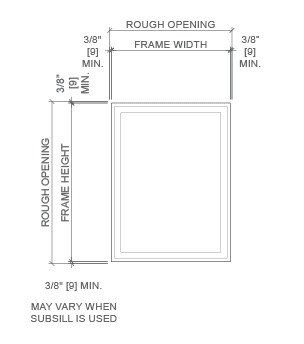

Perimeter Clearances

- To determine window opening size for typical installations, add 3/4" to frame width and height.

- For large windows, multiple windows, out-of-plumb openings, and/or in masonry construction, the need for additional jamb clearances should be reviewed.

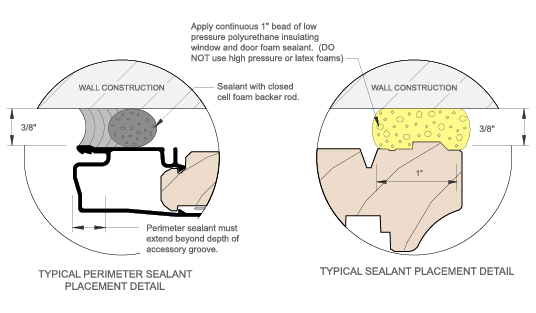

Typical Sealant Recommendations

Proper sealant placement is critical to window or door performance.

- When applying siding, brick veneer or other exterior finish material, leave adequate space between the unit frame and the exterior finish material for backer rod and sealant.

- Note: The sealant details shown are standard recommendations from the sealant industry. Contact your sealant supplier for recommendations and instruction for this or any other application.

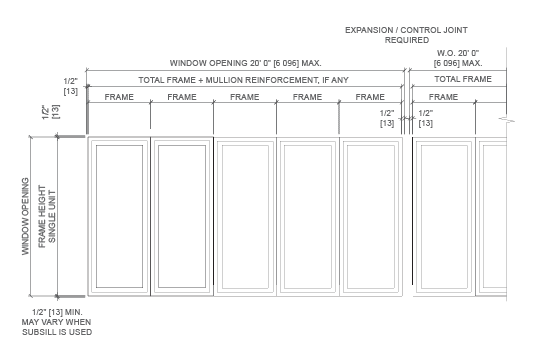

Horizontal Ribbons

Ribbon windows are an important design element for buildings with sweeping horizontal lines. Pella aluminum-clad wood windows offer elegant solutions for virtually any ribbon application. Our technical staff can assist you with expansion/control and reinforced mullion details to reconcile your design objectives with functional requirements.

Design Recommendations

In addition to the recommendations for punched openings, the greater width of horizontal ribbons often requires special head/jamb details, reinforcing mullions, expansion mullions, and subsills to resist wind loads, allow for construction tolerances, and provide adequate water management.

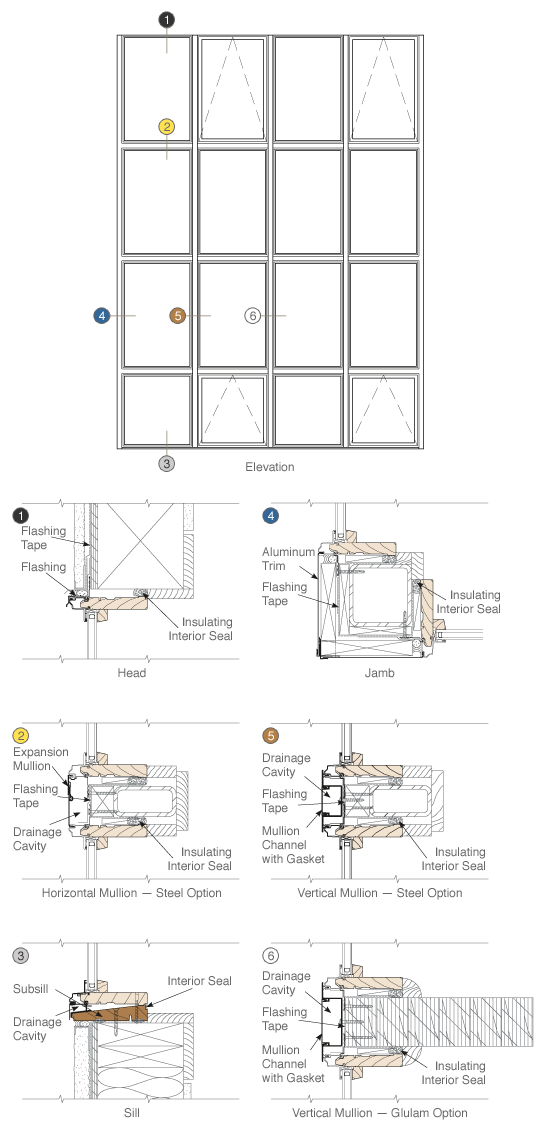

Typical Elevation

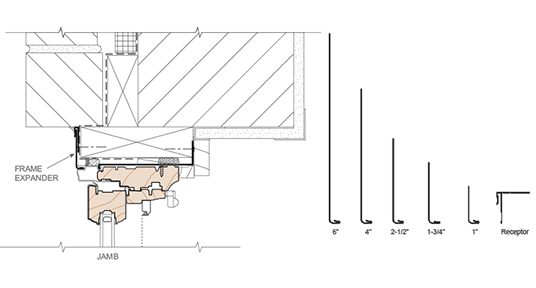

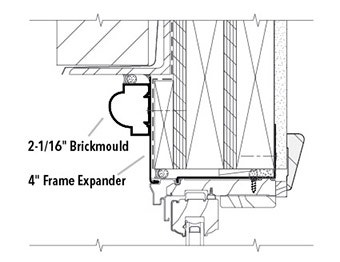

Typical Jamb Detail – with Frame Expander

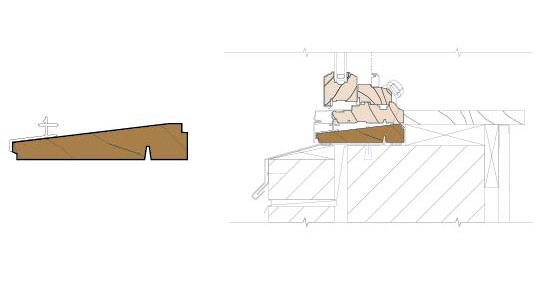

Typical Sill Detail – with Subsill

Subsill systems that weep incidental moisture to the exterior are recommended for water management in openings where the potential for water infiltration is increased and may not be adequately managed by the building weather barrier, flashings and drainage system.

Sample conditions include, but are not limited to:

- Increased level of exposure due to multi-story construction

- High weather exposure

- Recaulking would be difficult or unlikely

- Non-standard installation methods

- When there are multiple units joined within the opening

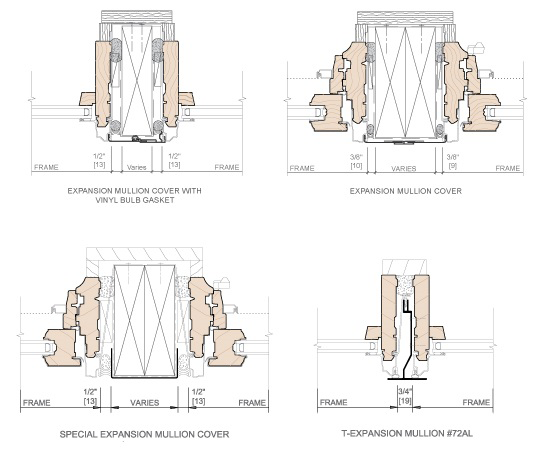

Typical Expansion Mullion Details

- For horizontal ribbons, expansion/control mullions are recommended every 20' maximum.

- Minimum 1/2" clearance is recommended at each jamb for openings greater than 10' in masonry openings.

- A variety of expansion mullion details are available.

Wood Vertical Stacks

When you want the visual impact of vertically stacked windows, the Pella Commercial technical staff can work with you to provide mullion reinforcement or intermediate dead-load support detailed to ensure compatibility with your aesthetic vision.

Design Recommendations

In addition to the recommendations for punched openings, the greater height of vertical stacks often requires special detailing, reinforcing mullions, intermediate dead load support, and subsills to resist structural loads, allow for construction tolerances, and provide adequate water management.

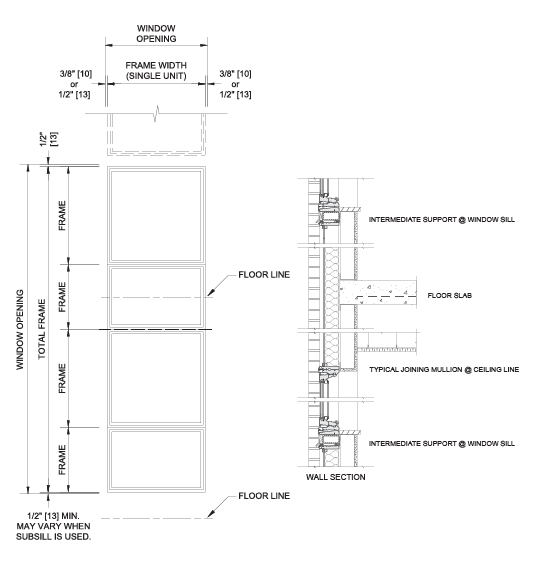

Typical Elevation/Section

Operable or fixed windows of the same width (4"-11" max) can be stacked vertically to a maximum height of 20' without intermediate support.

Typical Head Detail – with Frame Expander

- When window opening height is 12' to 20', see typical head detail to accommodate discrepancies in construction, floor and ceiling deflection, growth of unit assemblies and expansion movement.

- Frame expanders can be trimmed in the field.

- Receptors can be used to receive and trim the outside edge of the frame expander.

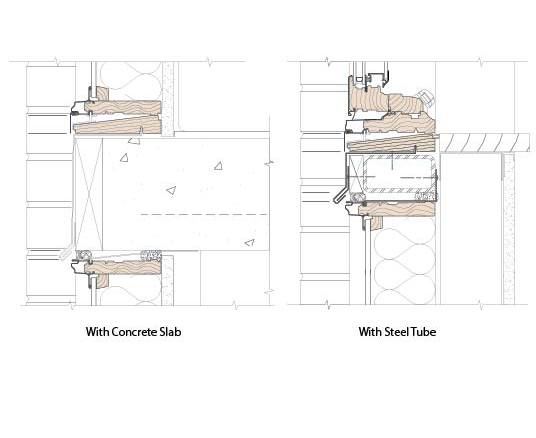

Typical Intermediate Support Details

- Intermediate dead load support is required for vertical stacks more than 20' in height.

- Many solutions are possible, including those shown.

- Recommendations on the Weight Limitations of Transoms over Doors Combinations Recommendations can be used as a guide for sizing dead load support.

- Check local code requirements when stacking windows past floor lines.

Typical Sill Detail – with Subsill

Subsill systems that weep incidental moisture to the exterior are recommended for water management in openings where the potential for water infiltration is increased and may not be adequately managed by the building weather barrier, flashings and drainage system.

Sample conditions include, but are not limited to:

- Increased level of exposure due to multi-story construction

- High weather exposure

- Recaulking would be difficult or unlikely

- Non-standard installation methods

- When there are multiple units joined within the opening

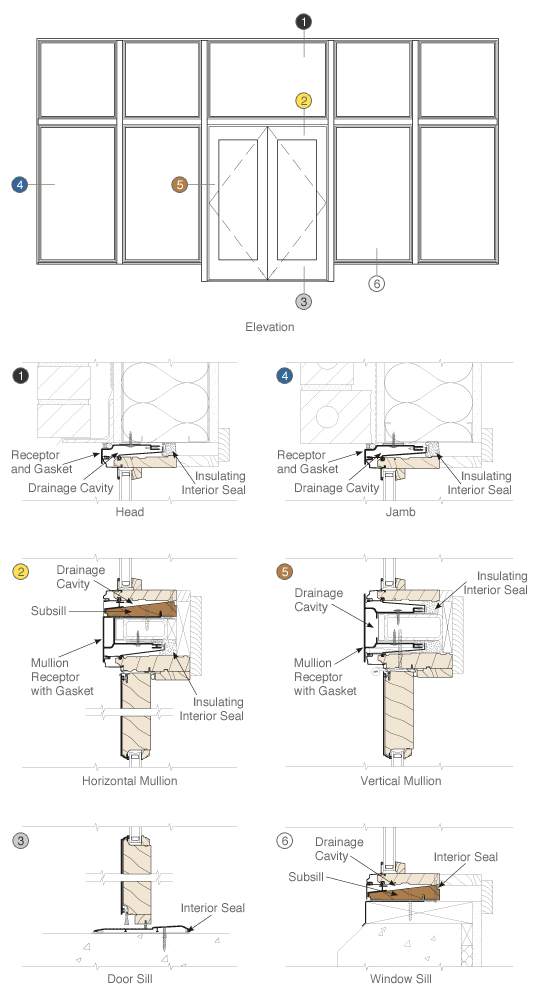

Wood Entrances and Storefronts

Design Recommendations

Storefronts and entrances include a combination of windows and doors that often require reinforcing mullions, expansion mullions, and subsills to resist wind loads while providing adequate water management.

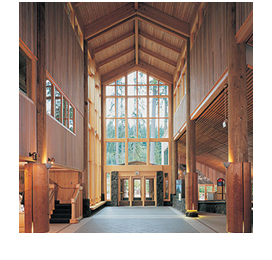

Wood Window Walls

When your project requires the visual impact and energy efficiency of aluminum-clad wood window walls, the Pella Commercial design team can partner with you early in the project to develop engineered fenestration solutions that meet your performance and load requirements without compromising your design vision. Plus, the beautiful wood interiors provide a unique design aesthetic.

Design Recommendations

Window walls may include a combination of windows and doors that require reinforcing mullions, expansion mullions, and subsills to resist wind loads while providing adequate water management.

Wood Combinations

This section explores the opportunities, requirements and limitations related to joining various combinations of standard Pella aluminum-clad wood windows and doors.

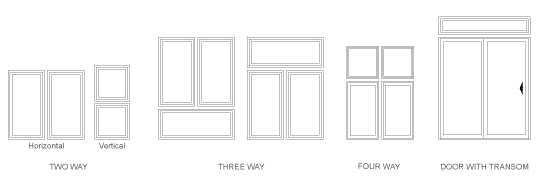

Typical Window and Door Combinations

Specific accessories and construction details must address the various conditions that are critical for the proper design of combinations of windows and doors such as

- Proper flashing

- Control joints to accommodate expansion and contraction

- Intermediate structural support

- Mullion reinforcing and its end anchorage to the rough opening

- Rough opening wall construction to accept loads transferred from window combination

Mullion Design

Placing windows and doors in a combination creates joints or mullions that may need structural reinforcing. Spread mullions can also be utilized to achieve an aesthetic element. In order to ensure that a given combination will withstand the design pressure, use the reinforcing tables on the following pages. These tables are organized by joint type and assembly type (factory vs. non-factory assembled). Use the graphical representation of each joint type to determine which joint type(s) are contained within the combination. The reinforcing tables consider structural performance only. See the Size and Performance Data page within each product section for single unit performance class and grade ratings.

IMPORTANT: Determining and meeting the structural load requirements and design of the rough opening is the responsibility of the architect or engineer. Window and door frame systems are not designed to support additional elements or components of the building wall system.

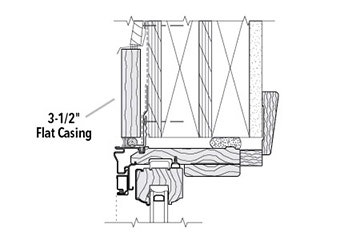

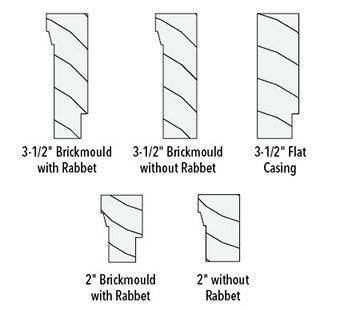

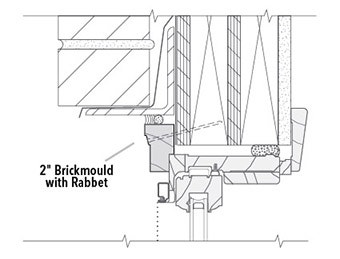

Wood Exterior Trim Options

Exterior trim options are designed to compliment Pella's wood and aluminum-clad wood product lines. Available in a wide variety of standard and custom profiles, they give you the ability to create distinctive architectural details in wood or low-maintenance aluminum.

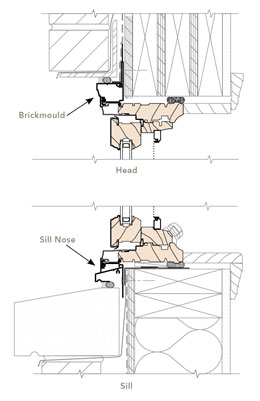

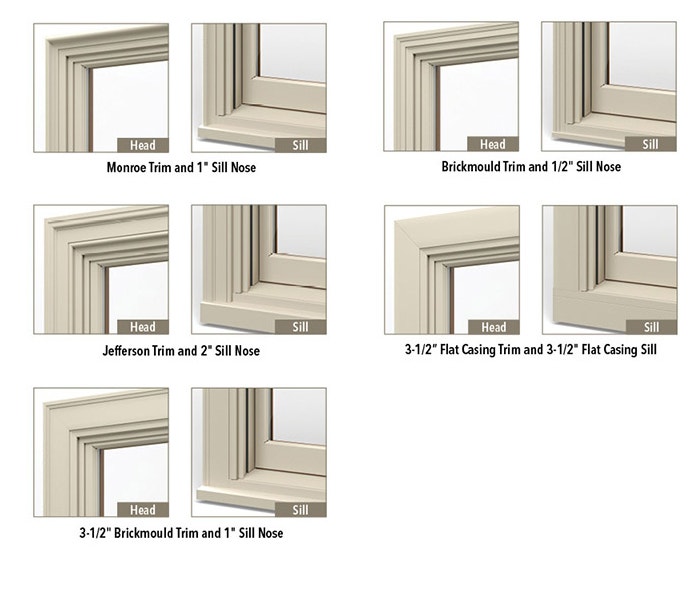

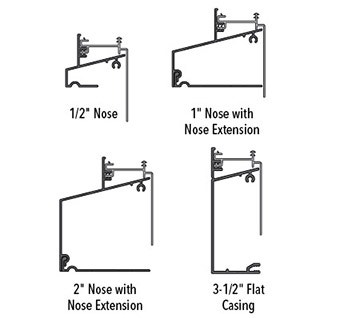

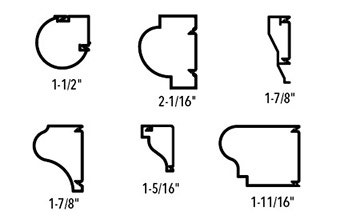

EnduraClad® Exterior Trim

Durable, Factory applied aluminum trim

- Prefinished with Pella's tough EnduraClad finish; matches Pella products

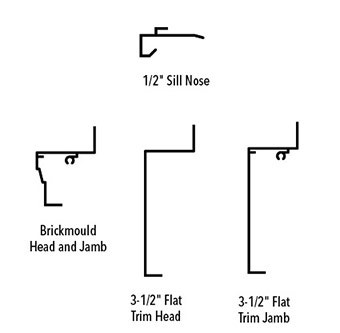

- Brickmould or 3-1/2" brickmould, 3-1/2" flat, Jefferson or Monroe profiles

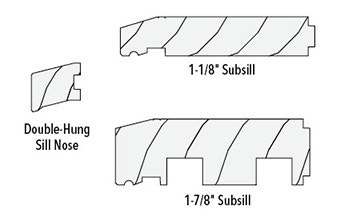

- Several sill nose options

- Custom profiles available

- Designed for aluminum-clad wood windows and doors

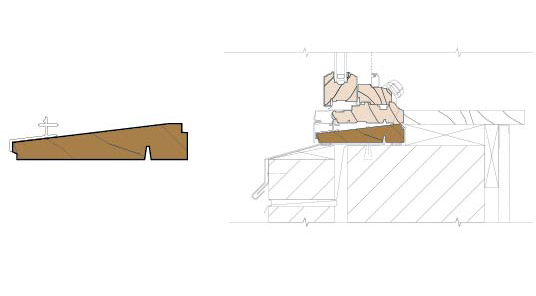

Sill Profiles

Installation Details

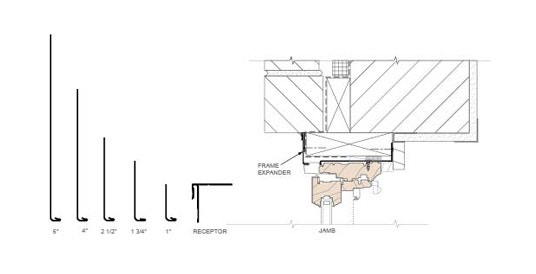

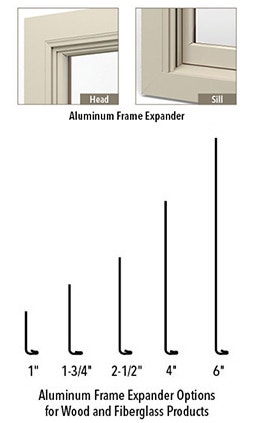

Frame Expander

Durable, snap-in trim that is adjustable to field conditions

- Prefinished; matches Pella products

- Provides the look of flat trim

- Aluminum brickmould can be attached to re-create the look of historical wood brickmould

- No metal brake required

- Cut-to-length kits, 96" or 144" lengths

- Available in widths from 1" to 6"

- Receptors are available to provide a finished edge

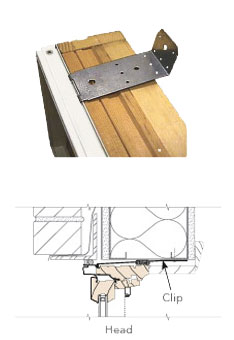

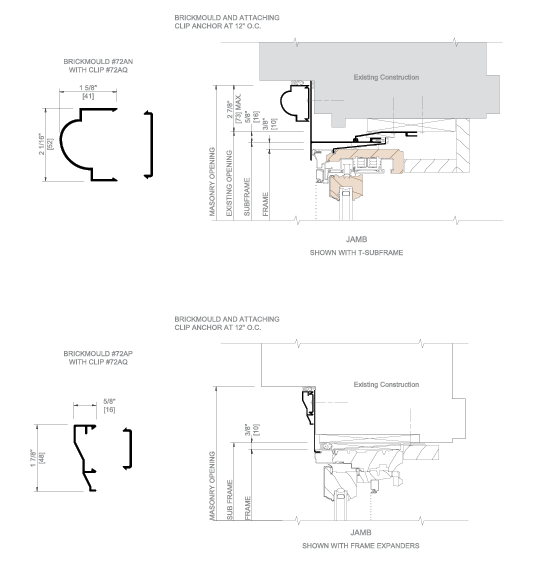

Aluminum Brickmould with Clip

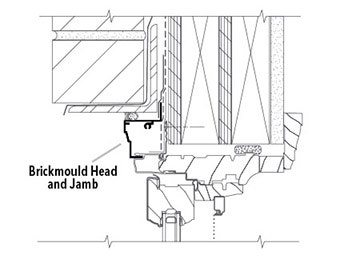

Head Detail

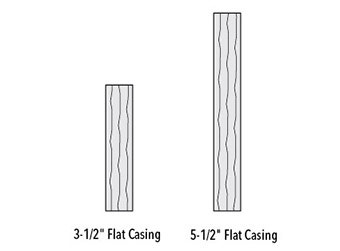

ROUGH/SMOOTH WOOD

Field-cut, protected, reversible wood trim

- Primed and ready for site finishing

- Grained or smooth appearance

- 10' lengths

- 3-1/2" or 5" flat widths, 3/4" thickness

Trim Profiles

Head Detail

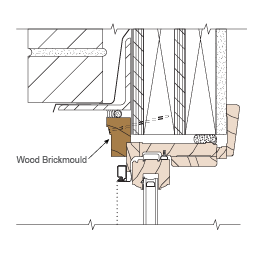

WOOD BRICKMOULD

Wood brickmould available factory-applied or in lineal lengths

- Available in primed Pine or Mahogany; ready for site finishing

- Straight or curved

- 1-7/8" or 3-1/2" brickmould or flat trim with 1-1/2" or 1-7/8" sill nose/subsill

- Standard and custom profiles available

- Designed for wood exterior windows and doors only

Trim Profiles

Sill Profiles

Head Detail

TRADITIONAL TRIM

Durable, field-cut aluminum snap-in trim

- Prefinished; matches window frame

- 96" or 144" lengths

- 3" flat or 1-1/2" brickmould

- Custom brickmould profiles available

- Straight or curved

Trim and Sill Profiles

Head Detail

Interior Trim Options

The industry's most popular wood interior trim styles provide a vast range of options that are true to a home's architectural style and decor. All profiles are available in Pine; select profiles are available in Oak. Pine trim styles are available prefinished in 11 stain colors or 5 paint colors, or unfinished. Oak trim styles are available prefinished with 11 stain colors or unfinished.

Wood interior trim from Pella:

Available by the lineal foot

- Offered in 72"-96", 144" lineal for flexibility.

- Ready for cutting and installation at the job site

- Curved trim is ready to be trimmed to fit on the jobsite, and works with many curved openings (windows, doors and transoms)

- Can be ordered separately

Trim Styles Available

All profiles and accessories are available in Pine; select profiles and accessories are available in Oak. 34 unique profiles.

- Colonial - Simplicity and symmetry authentic to the traditional style. 13 profiles.

- Craftsman - Lasting influence and attention to detail mold the decorative features. 5 profiles.

- Provincial - Curved arches and soft lines create stylish effects from the simple to the extravagant. 9 profiles.

- Ranch - Smooth transitions and a long, low profile highlight the style options. 7 profiles.

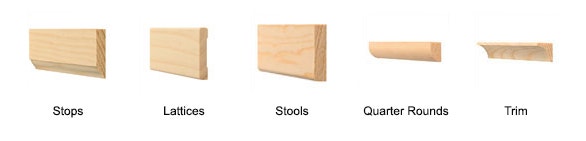

Accessories

Coordinate accessory trim to accents in the home with these beautiful choices.

- Stops

- Lattices

- Stools

- Quarter Rounds

- Trim

Renovation

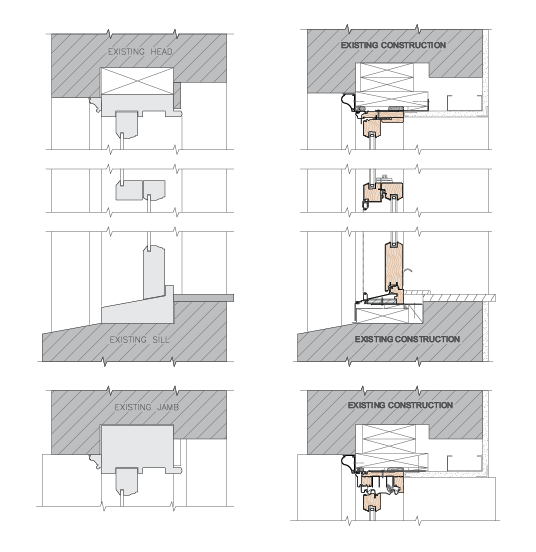

Complete Tear-Out of Existing Frame and Sash

Applicable when a complete tear-out is necessary for historical, aesthetic or structural considerations.

- Custom-size units available

- Good for virtually any existing opening

Depending on the needs of the project, wood or aluminum-clad wood windows can be used to replace existing wood or metal windows when a complete tear-out of the existing frame and sash is required.

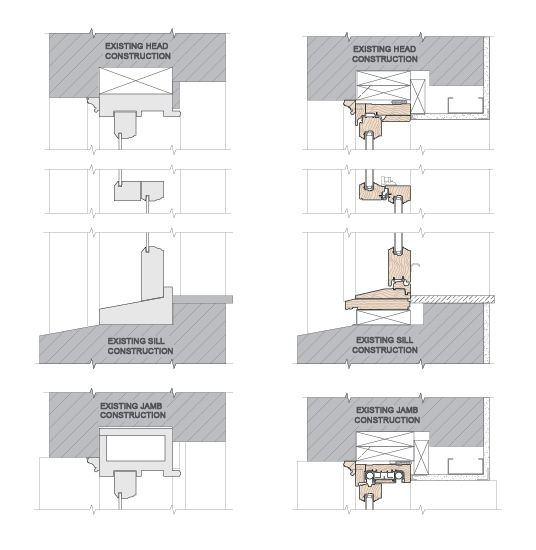

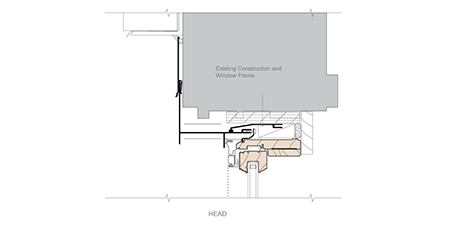

Replace with Aluminum-Clad Wood Windows and Frame Expanders

There are many options available for replacing the existing wood or metal windows with aluminum-clad wood windows. One approach is to replace the existing frames with wood blocking and cover the blocking on the exterior with the Pella Frame Expander System.

- It provides an economical method for replacing old wood or metal windows

- Pella aluminum-clad windows and doors have an accessory groove that allows for the use of the frame expander system

- Made of low-maintenance aluminum cladding that perfectly matches Pella products, these frame expanders can be used to cover the new blocking

- Windows need to be accessible from the exterior to use this type of installation

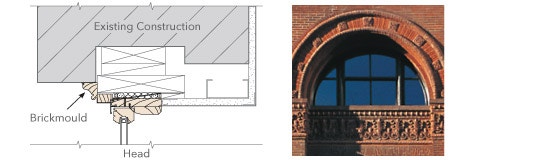

Replace with Aluminum-Clad Wood Windows and Brickmould

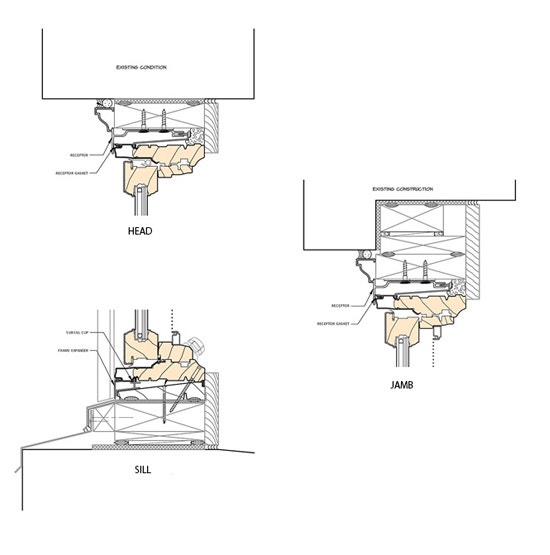

Replace with Aluminum-Clad Wood Windows, Receptor and Subsill

A second approach is to replace the existing wood or metal windows with aluminum-clad wood windows and a Pella receptor and subsill system. Receptors are often used for multistory buildings requiring installation from the interior or when a more robust installation method is desired.

Replace with Wood Windows

There are also many options available for replacing the existing wood windows with new wood windows. One approach that involved a complete tear-out of the existing wood windows is shown below. The details for both the existing wood windows and the new wood windows are included.

- The first step is to replace the existing wood frames with new treated wood blocking at the head and jambs

- Then the new wood window can be attached to the blocking with clips or anchored to the blocking through the window frame

Retain Existing Frame and Replace Sash

In contrast to the complete tear-out approach, the more commonly used approach to window replacement recognizes that the frame and trim that is already installed in the exterior wall may still be fully serviceable, but the operable or fixed sash may need replacing.

- It saves on the labor costs associated with the complete tear out approach, but also assumes that other considerations can be met through the re-use of the existing frame and trim.

- Reuse may enhance historic or maintenance considerations depending on the project.

- Pella offers a variety of installation systems designed to accommodate this approach.

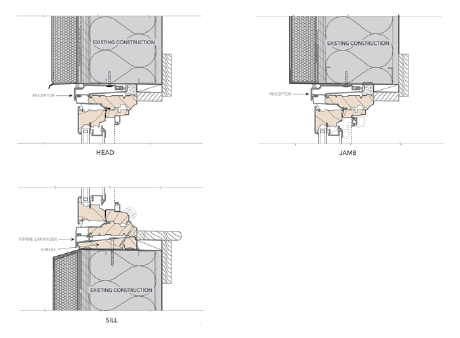

Replacement of Sash Only Using Pocket Installation

Applicable when the existing frames are in good condition and only the sash needs to be replaced.

- Fully assembled Precision Fit® double-hung, casement, awning and fixed windows

- Slides easily into existing pocket

- Trim, wall coverings, paint and plaster are usually not disturbed

- Reduces cost and inconvenience compared to a complete tear-out

Installation Details

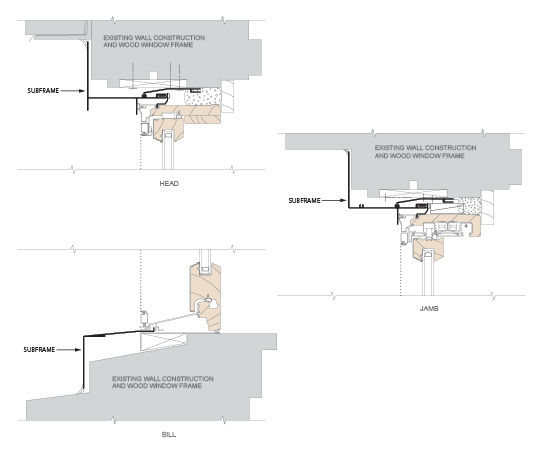

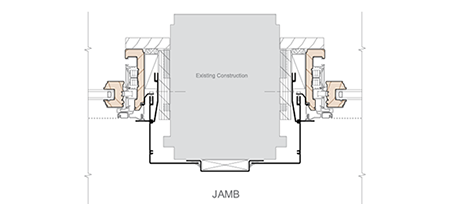

Replacement of Sash Only Using Standard Subframe System

Applicable when replacing wood windows.

- Aluminum subframe is preassembled and installed into openings

- Conceals existing wood window frame to become "receptor" for new window

- Allows installation from inside building

- Reduces labor costs and eliminates need for exterior scaffolding and its expense

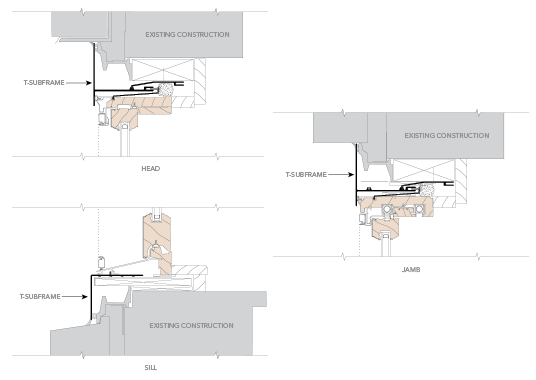

Replacement of Sash Only Using T-Subframe System

Applicable when replacing metal windows.

- Aluminum subframe is preassembled and installed into openings

- Conceals existing wood window frame to become "receptor" for new window

- Allows installation from inside building

- Reduces labor costs and eliminates need for exterior scaffolding and its expense

Profiled Receptor

Applicable when replacing wood or metal windows.

- Profile of subframe typically matches profile of existing window frame and brickmould

- Aluminum subframe is preassembled and installed into openings

- Conceals existing wood or metal window frame to become "receptor" for new window

- Allows installation from inside building

- Reduces labor costs and eliminates need for exterior scaffolding and its expense

Installation Accessories for Standard Subframe and T-Subframe - Subframe Expander

Subframe expanders are used to expand the width of the subframe flange and are often used on curve-top window openings with rectangular windows.

Subframe Mullion Trim

When there are several window openings in a row, the mullion detail shown below can be used to enable the use of subframes in all of the openings while covering the exposed wood between subframes.

Subframe Mullion Trim - Aluminum brickmoulds

Aluminum brickmoulds can be added to the face of the subframe flange to match the profile of the historic wood brickmould.

Field Measurement Guides

- Field measurement guides are available for window replacement projects where only the window sashes are removed and the existing frame is left in place.

- These guides identify the important dimensions required to design the window replacement solution.

- Guides are available for existing wood and metal windows.